SHENZHEN, GUANGDONG, CHINA, January 26, 2026 /EINPresswire.com/ — As luxury and premium accessory brands raise expectations around durability, dimensional precision, and long-term quality consistency, the leather goods hardware sector is undergoing a material transition. In this context, China Luxury Bag Frame Hardware Manufacturer YIBI is working alongside international brands as the industry increasingly shifts from traditional alloys toward stainless steel for critical hardware components. Functional elements such as buckles, chains, zipper pulls, snap hooks, and especially bag frames are now evaluated as structural systems rather than interchangeable decorative parts, reflecting a broader reassessment of material performance standards in modern luxury handbags.

Across the mid-to-high-end leather goods segment, brands are gradually moving away from copper-based and zinc alloys in favor of stainless steel, citing the need for higher structural strength, improved surface stability, and reduced long-term performance risk during daily use. This transition reflects evolving design requirements, including larger bag formats, higher load demands, and increased expectations for consistent opening-and-closing performance. Within this shift, YIBI focuses its manufacturing capabilities on stainless steel hardware systems intended to support these changing requirements.

Industry Shift: Material Performance Driving Design Decisions

For many years, brass and zinc alloy were widely used in leather hardware due to ease of casting and established production methods. However, as product usage scenarios expand, the limitations of these materials have become more apparent.

Copper-based alloys such as brass are comparatively soft and more susceptible to deformation under long-term mechanical stress. Surface oxidation and discoloration can occur in humid or high-contact environments, and plated finishes may show wear over time. Zinc alloys, while suitable for certain applications, generally offer lower structural strength and may present higher risks of cracking or distortion in larger or load-bearing components, particularly in mechanisms requiring repeated movement.

By contrast, stainless steel—particularly 316L stainless steel—offers higher tensile strength, improved corrosion resistance, and greater dimensional stability. These characteristics have led many brands to view stainless steel not as an optional upgrade, but as a material better aligned with current expectations for structural reliability and lifecycle performance in premium leather goods.

Bag Frames as a Key Driver of Stainless Steel Adoption

Among leather hardware components, bag frames represent one of the most structurally demanding applications. Unlike decorative elements, frames define the opening geometry, closure precision, and long-term shape retention of a handbag.

In daily use, bag frames are exposed to repeated opening and closing cycles, external pressure during transport and storage, and the weight of larger bag bodies and contents. When produced using traditional alloys, frames may experience gradual deformation, misalignment, or inconsistent closure performance over time.

Stainless steel bag frames offer improved rigidity and resistance to deformation, supporting consistent alignment and closure behavior throughout extended use. These properties are increasingly relevant for large-capacity handbags, structured fashion designs, travel-oriented leather goods, and products requiring slim profiles with higher load tolerance.

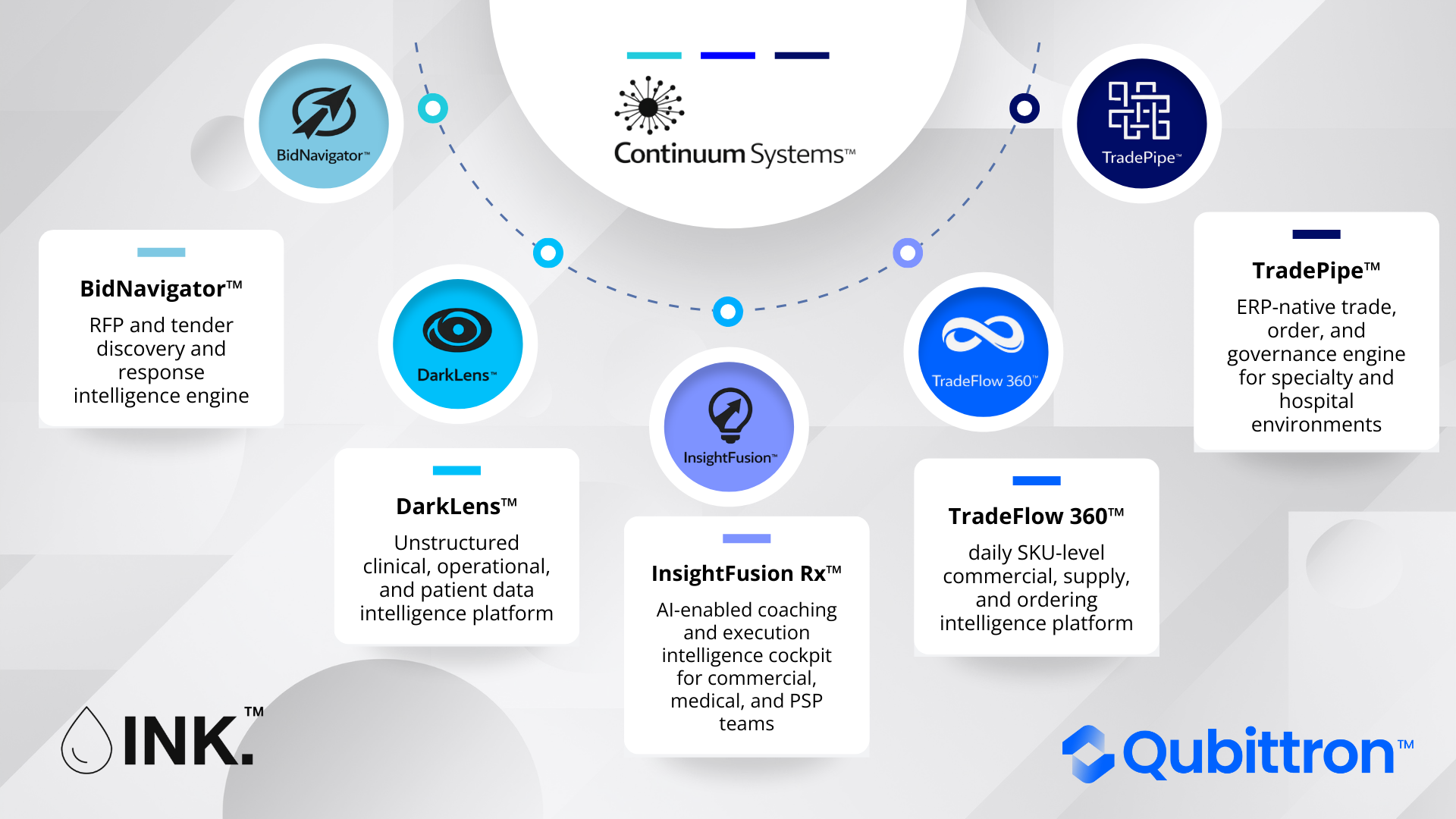

YIBI’s Role as a Stainless Steel–Focused Hardware Manufacturer

YIBI operates as a leather hardware manufacturer with a defined focus on stainless steel materials. Rather than offering mixed-material solutions, the company concentrates on developing stainless steel components designed to meet the structural, functional, and finishing requirements of premium leather brands.

Its OEM and ODM manufacturing scope includes stainless steel bag frames, chains, buckles, clasps, snap hooks, zipper pulls, and coordinated hardware sets. This material-focused approach supports brands seeking consistency in performance, surface behavior, and long-term quality across product lines.

Engineering Considerations in Stainless Steel Hardware Production

In bag frame manufacturing, YIBI applies controlled tolerance management, hinge structure optimization, and standardized surface finishing processes to support dimensional accuracy and functional stability over repeated use cycles.

To support design consistency, the company also supplies coordinated stainless steel hardware sets, enabling uniform tone, finish behavior, and tactile characteristics across multiple components and SKUs. From a performance perspective, stainless steel hardware offers resistance to sweat, humidity, and corrosion, along with reduced deformation risk under load and more stable surface behavior over time.

Collaboration with Brand Development Teams

YIBI works with international brand teams through structured OEM and ODM workflows, providing technical input during early-stage design, sampling, testing, and production planning. This collaboration is particularly relevant in bag frame development, where early decisions around material selection and structural design can directly influence long-term product performance and user experience.

Conclusion

The increasing adoption of stainless steel in leather goods hardware reflects a broader shift in how premium brands define durability, functionality, and long-term value. As material expectations evolve, stainless steel is becoming a reference standard for structural hardware components, particularly bag frames.

By focusing on stainless steel hardware engineering, YIBI positions itself as a manufacturing partner aligned with these industry changes, supporting brands seeking reliable structural performance and consistent quality outcomes in luxury leather goods.

For more information, visit YIBI Group on LinkedIn:

https://www.linkedin.com/company/yibi-group/

Yibi Group

Yibi Group

+86 199 2534 3470

adam@chinayibi.com

Legal Disclaimer:

EIN Presswire provides this news content “as is” without warranty of any kind. We do not accept any responsibility or liability

for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this

article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

![]()